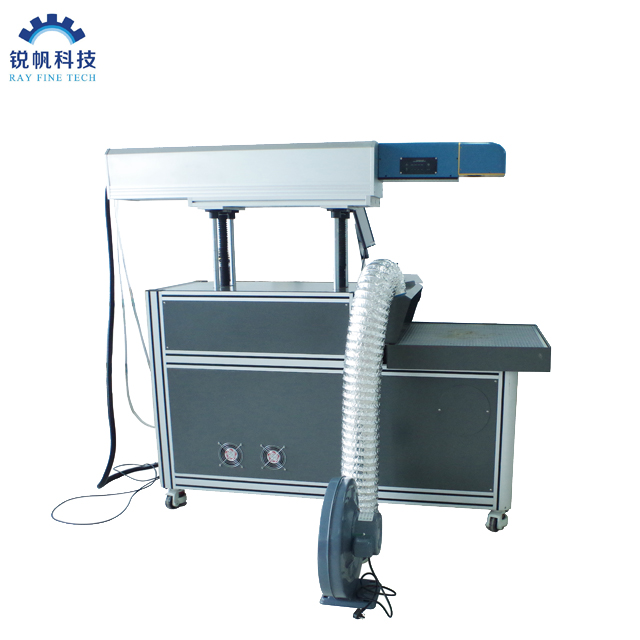

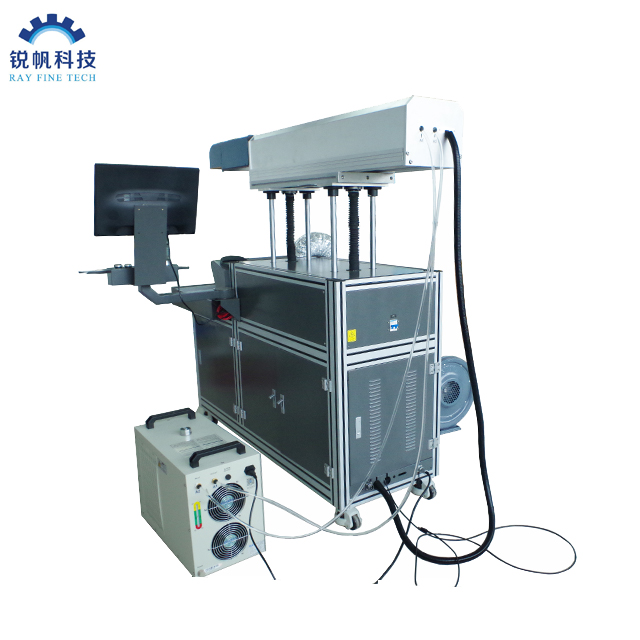

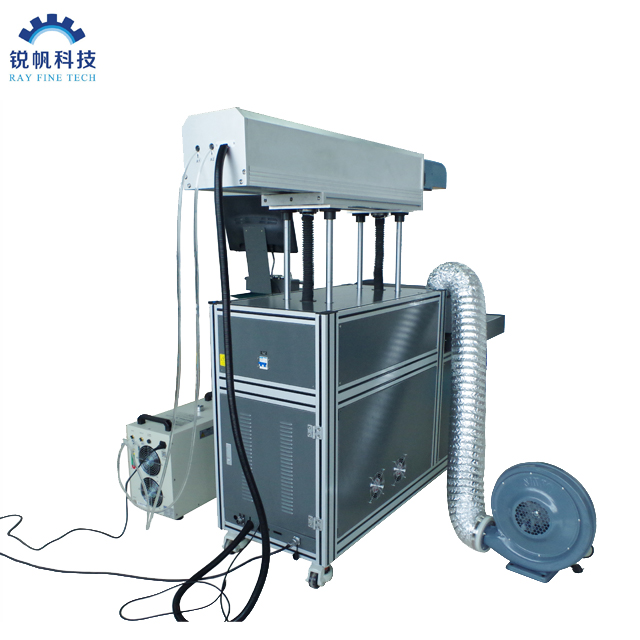

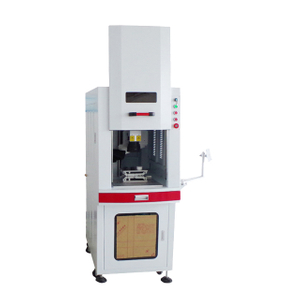

3D Dynamic Focus Co2 Galvo Laser Cutting Machine

Laser cutting is a very flexible way of processing, because it does not like other traditional methods that need templates or molds, change the cutting path and shape is particularly convenient, and therefore more suitable for small batch production.

The use of laser marking head for cutting is very suitable for greeting cards such products, cutting routes can be replaced at any time, and then fine patterns can be cut out, while making custom cutting possible.

Machine advantages:

1. High cut/engrave speed

This series machine adopts advanced US Galvo scanning system. The cutting/engraving speed can reach 7000mm/s. Fulfill the request of factory mass production.

2. Precise process

With US RF metal laser tube, this machine has finest laser beam, to cut and engrave very precisely. Especially when you cut paper card, the cutting edge is very smooth and thin.

3. Forever lasting marking

Laser is non contact process, there is no distortion. As laser marking is to gasify the surface of material, the marking will laser forever.

4. Flexible process

You just need to change design in software, then all different size/shape pattern can be realized. It is very convenient for sampling or changing products. No need cost for template.

5. Easy operation

Adopting integrated structure with Auto focusing technology and humanized operation design. Making the laser marking as easy as printing.

6. Minimal owner ship cost

No need any maintenance, long life, small volume, suits for working in atrocious working conditions.

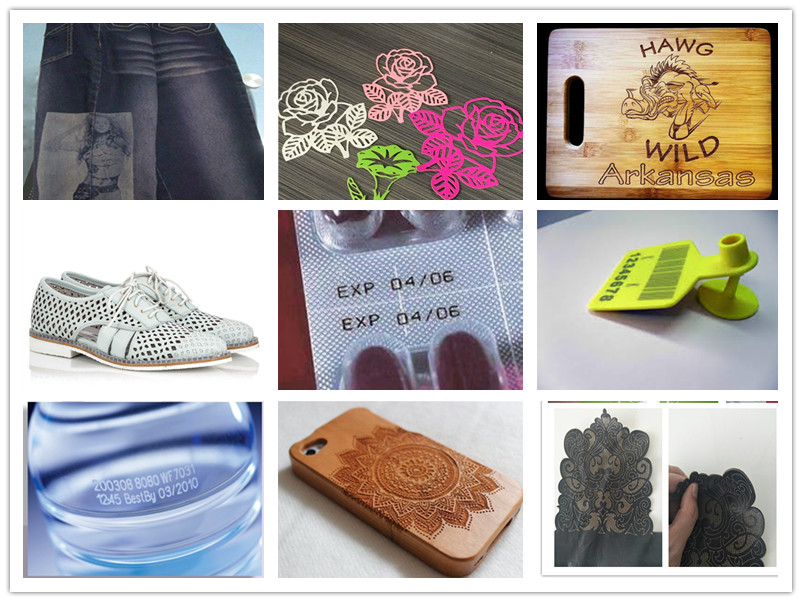

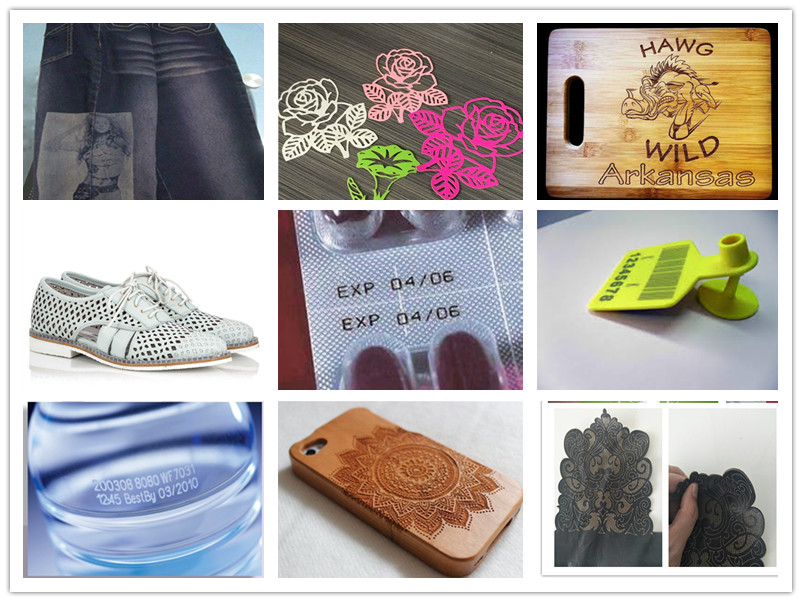

7 Wide application

This machine can mark, engrave, cut, hollow on almost all non-metal material, like wood, acrylic, plastic, marble, paper, glass, leather, textile, bamboo, PVC, rubber and so on.

It is widely applied in industry like electronic, machinery, garments, artwork, gifts, greeting card, packing, advertisement ect.

It can process with any pattern, signs, bar code, letters, serial number as request.

Applicable materials:

This machine can perfectly mark/cut on non-metal material like wood, acrylic, paper card, PVC, rubber, plastic,glass,LGP fur, leather, textile, denim with high speed. Suits factory mass production.

Applicable industries:

It is widely applied in industry like electronic, machinery, garments, artwork, gifts, greeting card, packing, advertisement ect.

It can process with any pattern, signs, bar code, letters, serial number as request.

Samples:

Paper Cards:

English

English