Views: 194 Author: Site Editor Publish Time: 2025-07-06 Origin: Site

Fiber laser cutting machines have become a cornerstone of modern metal fabrication thanks to their precision, speed, and versatility. However, one persistent challenge operators often face is nozzle clogs and damage, which can drastically affect cutting quality, consistency, and even machine longevity. Preventing such issues is crucial for maintaining performance and reducing operational downtime. In this article, we'll explore practical strategies and insights to keep your fiber laser cutting nozzle clean, functional, and efficient over time.

The nozzle in afiber laser cutting machine is a small but essential component that directly influences beam alignment, gas flow, and cut quality. It serves as the exit point for assist gases like nitrogen or oxygen, which help remove molten material from the cut zone. Misalignment, blockages, or damage to the nozzle can result in irregular cuts, burrs, and even severe machine errors.

To understand how to prevent clogging or damage, it's important to grasp what exactly causes these issues in the first place. The nozzle's narrow opening can easily collect spatter, slag, or dust, especially during high-speed or high-temperature cutting. Over time, this buildup reduces the nozzle's effectiveness, potentially causing back reflections or beam deflection—both of which can be dangerous and costly.

One of the most common culprits behind nozzle blockages is spatter accumulation. During the cutting process, molten metal droplets may fly back toward the nozzle, sticking to its outer or inner surface. This buildup narrows the gas channel and disrupts gas flow, compromising cut quality.

High-speed operations and thicker materials are particularly prone to this issue. The higher the heat and pressure involved, the greater the chance that spatter will accumulate on the nozzle tip. Without regular cleaning, these deposits can harden, causing partial or total blockage.

Another frequent cause of damage stems from maintaining the wrong stand-off distance—the space between the nozzle and the material surface. If the nozzle is too close, it can physically scrape against the material, especially during rapid movements or uneven sheets, leading to warping or deformation. Conversely, being too far reduces the efficiency of gas flow and beam focus, increasing the risk of overheating and clog formation.

Using low-grade assist gases or gases contaminated with moisture or oil can lead to internal nozzle residue buildup. These impurities can react with heat and metal dust to form sticky particulates that adhere to nozzle walls, creating hidden blockages over time.

Preventative maintenance is key to prolonging nozzle life and ensuring uninterrupted operations. While this may seem time-consuming, it saves significantly more time and cost compared to unplanned downtime or nozzle replacement.

Operators should clean the nozzle at the start and end of every shift. Use a soft, lint-free cloth to wipe away visible spatter or dirt. For internal cleaning, nozzle cleaning needles or soft-bristle brushes can gently remove blockages. Ensure the nozzle orifice remains circular and free of deformities. A misshapen nozzle can lead to misaligned cuts and excessive beam reflection.

Inspect for discoloration, cracks, or burn marks. Any sign of wear indicates it's time to either clean more thoroughly or consider replacement.

Applying a high-temperature-resistant anti-spatter spray or coating to the nozzle exterior can help reduce the adhesion of molten metal droplets. This protective layer makes it easier to wipe off accumulated materials and reduces long-term clogging.

Alternatively, some systems support protective nozzle shields or covers that serve as sacrificial barriers. These can be easily replaced after each job cycle to keep the main nozzle in pristine condition.

Not all cutting applications are created equal, and choosing the appropriate nozzle size and shape can help minimize clog risk. Generally, fiber laser nozzles come in single and double nozzle types, with orifice diameters ranging from 1.0 mm to 3.0 mm.

Single nozzles are ideal for applications requiring high-pressure oxygen or for cutting thinner metals. Double nozzles, on the other hand, are more suited for nitrogen-assisted cutting and better gas flow control, which reduces backflow and spatter accumulation.

Choosing the correct nozzle type for your material and thickness not only improves cut quality but also extends nozzle life and reduces clog incidents.

| Material Type | Material Thickness | Recommended Orifice Size | Assist Gas |

|---|---|---|---|

| Mild Steel | <3 mm | 1.0–1.2 mm | Oxygen |

| Stainless Steel | 3–6 mm | 1.5–2.0 mm | Nitrogen |

| Aluminum | >6 mm | 2.0–2.5 mm | Nitrogen |

Always consult your machine's cutting parameter guide to match the appropriate nozzle to your job specifications.

Proper nozzle alignment is not just about getting clean cuts—it's also about preventing premature wear and dangerous reflections. A poorly aligned nozzle can deflect the laser beam, concentrating energy on the nozzle edges, which leads to burning, warping, or cracking.

Regularly check nozzle concentricity using calibration tools or software-supported vision systems. If your laser cutting machine supports auto-focus or capacitive height sensing, recalibrate these functions weekly to ensure the nozzle maintains consistent height throughout the cutting process.

Also, make sure the beam path is clean and mirrors or lenses (if applicable) are dust-free. Impurities in the optical system can scatter the laser beam, increasing nozzle exposure to irregular energy distribution and thermal stress.

There's no one-size-fits-all answer, as replacement depends on usage, materials, and maintenance. However, on average, a nozzle should be replaced every 1–2 weeks in high-volume shops. If you notice frequent clogs, irregular cuts, or degraded edge quality, it's time to inspect or replace the nozzle.

Yes. A damaged nozzle can alter the assist gas flow, leading to improper expulsion of molten material and increased dross formation. It can also reflect or scatter the laser beam, reducing focus accuracy and potentially damaging optical components inside the laser head.

Most fiber laser cutting nozzles are made from copper or brass, which offer excellent thermal conductivity and resistance to heat. Some high-end variants may be coated with chromium or other anti-oxidation materials to enhance durability.

Beyond routine cleaning and proper selection, there are several additional strategies you can adopt to maximize nozzle lifespan and cutting quality.

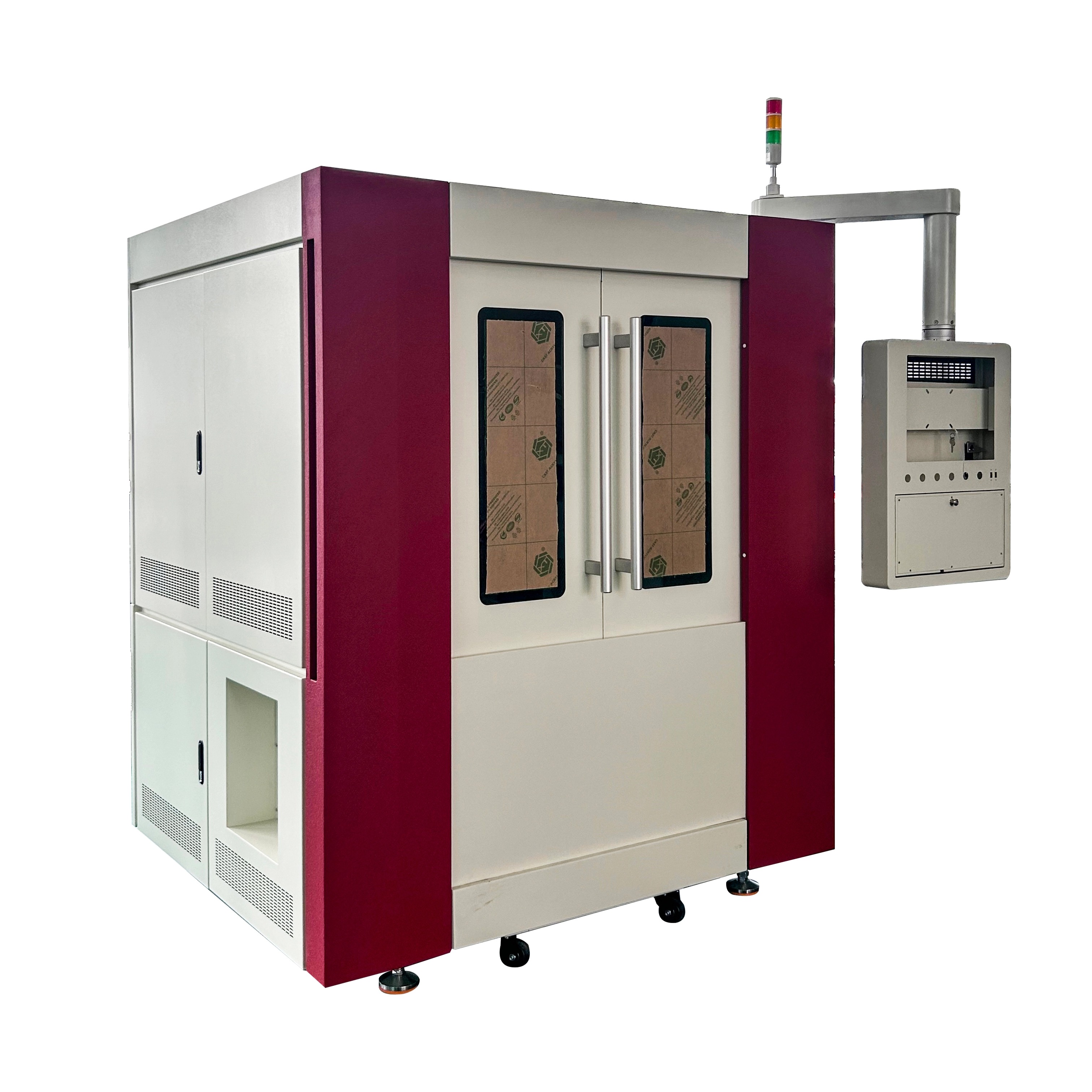

Operate the machine in a dust-controlled environment. Ambient particles can be drawn into the assist gas stream and settle in the nozzle. Installing air filters or sealed enclosures can reduce airborne contaminants.

Nozzle care isn't just the technician's job—it should be embedded into your operating procedures. Ensure your team understands the importance of nozzle condition and follows consistent Standard Operating Procedures (SOPs) for setup, inspection, and cleaning.

Post visual guides or create a checklist for daily and weekly nozzle care. Investing in training and process discipline can significantly reduce the risk of unexpected clogs and productivity loss.

A clogged or damaged nozzle is more than just a maintenance headache—it can compromise your entire fiber laser cutting operation. By understanding the causes, implementing routine maintenance, choosing the right components, and maintaining proper calibration, you can dramatically extend the life of your nozzles and improve the consistency of your cuts.

Remember: the nozzle may be small, but its impact is enormous. Taking proactive steps to care for it is not just maintenance—it's an investment in uptime, quality, and operational excellence.