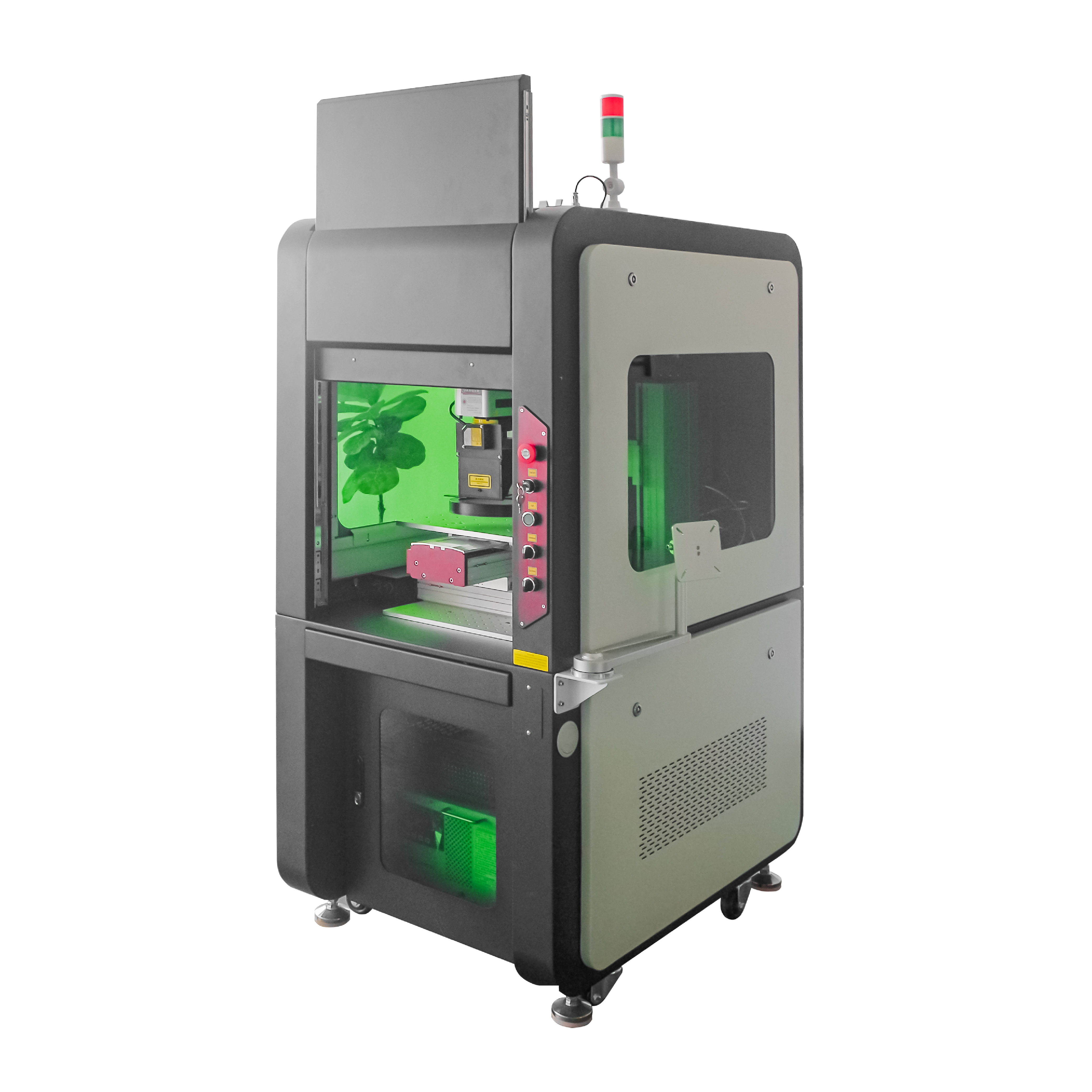

What is wafer dicing machine?

Wafer dicing machines are essential for creating integrated circuits (ICs), sensors, and other microelectronic components that power devices like smartphones, computers, and automotive electronics.

Key Advantages of Wafer Dicing Machines

High Precision Cutting

Rayfinetech’s wafer dicing machines provide exceptional cutting accuracy with advanced alignment systems and high-speed diamond blades, ensuring minimal kerf loss and precise die separation.

Advanced Cooling System

The machines are equipped with efficient cooling systems that reduce heat buildup during the cutting process, preventing damage to delicate wafers and improving cutting longevity.

Flexible Operation Modes

Rayfinetech’s dicing machines offer versatile operation modes, allowing customization for various wafer sizes, materials, and cutting patterns, enhancing flexibility for different production needs.

Reliable Performance

Built with robust components and precise engineering, these machines ensure long-term reliability and consistent performance, reducing maintenance needs and ensuring high yields in mass production.

Hot Products

Why Choose Rayfinetech

Rayfine Technologies offers advanced, high-precision wafer dicing machines tailored for industries like semiconductor, automotive, and medical. With reliable performance, customizable solutions, and enhanced productivity features, their machines deliver consistent quality. Backed by strong after-sales support, Rayfine ensures maximum efficiency and innovation.

Advanced Technology & Precision

Rayfine Technologies offers state-of-the-art wafer dicing machines equipped with advanced technology for high-precision cutting. Their machines are designed to deliver maximum accuracy in slicing semiconductor wafers into individual chips, ensuring high-quality and reliable microelectronic components.

Customized Solutions

Rayfine Technologies provides tailored solutions for a wide range of industries including semiconductor, automotive, LED, medical, and more. Whether you need high-volume production or precision cutting for specialized applications, Rayfinetech's machines are adaptable to meet specific requirements.

High Reliability and Durability

The company's wafer dicing machines are built with robust materials and engineering to ensure long-term reliability and minimal maintenance. This durability translates to reduced downtime and consistent performance, which is crucial in fast-paced manufacturing environments.

Enhanced Efficiency & Productivity

With features like automated alignment, high-speed cutting, and programmable controls, Rayfine's machines significantly enhance production efficiency. Their machines help reduce cycle times, improve throughput, and lower operational costs, making them a valuable investment for manufacturers.

Comprehensive After-Sales Support

Rayfine Technologies offers strong after-sales support, including installation, training, and ongoing maintenance services. Their expert team ensures that clients get the most out of their equipment and helps resolve any technical issues promptly to minimize disruptions in production.

Commitment to Quality & Innovation

Rayfine Technologies is dedicated to continuous innovation and quality improvement. By investing in research and development, the company strives to stay at the forefront of wafer dicing technology, ensuring that their machines deliver the best performance and reliability to meet the evolving demands of their clients.

Applications Of Wafer Dicing Machine

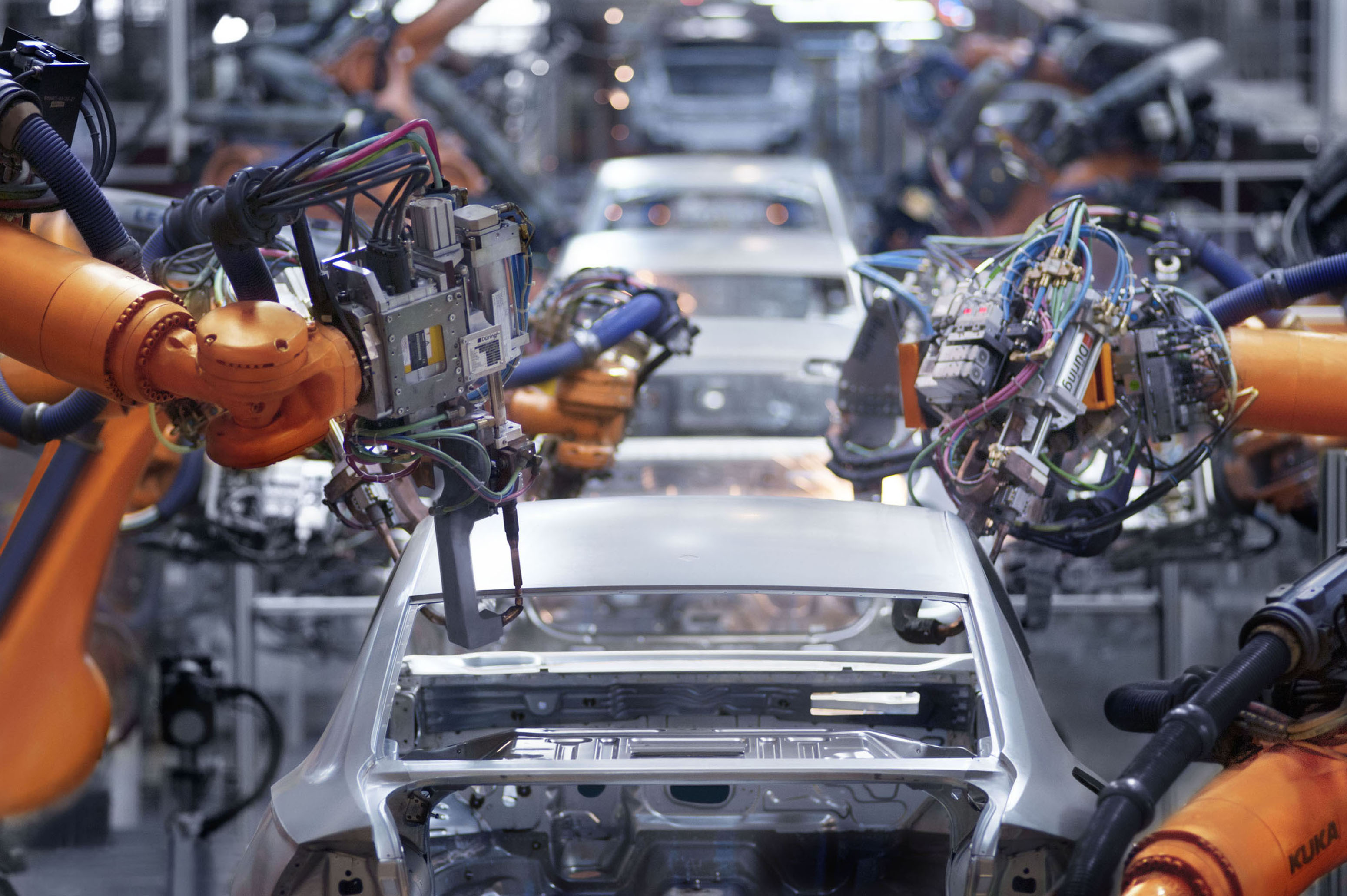

Automotive Industry

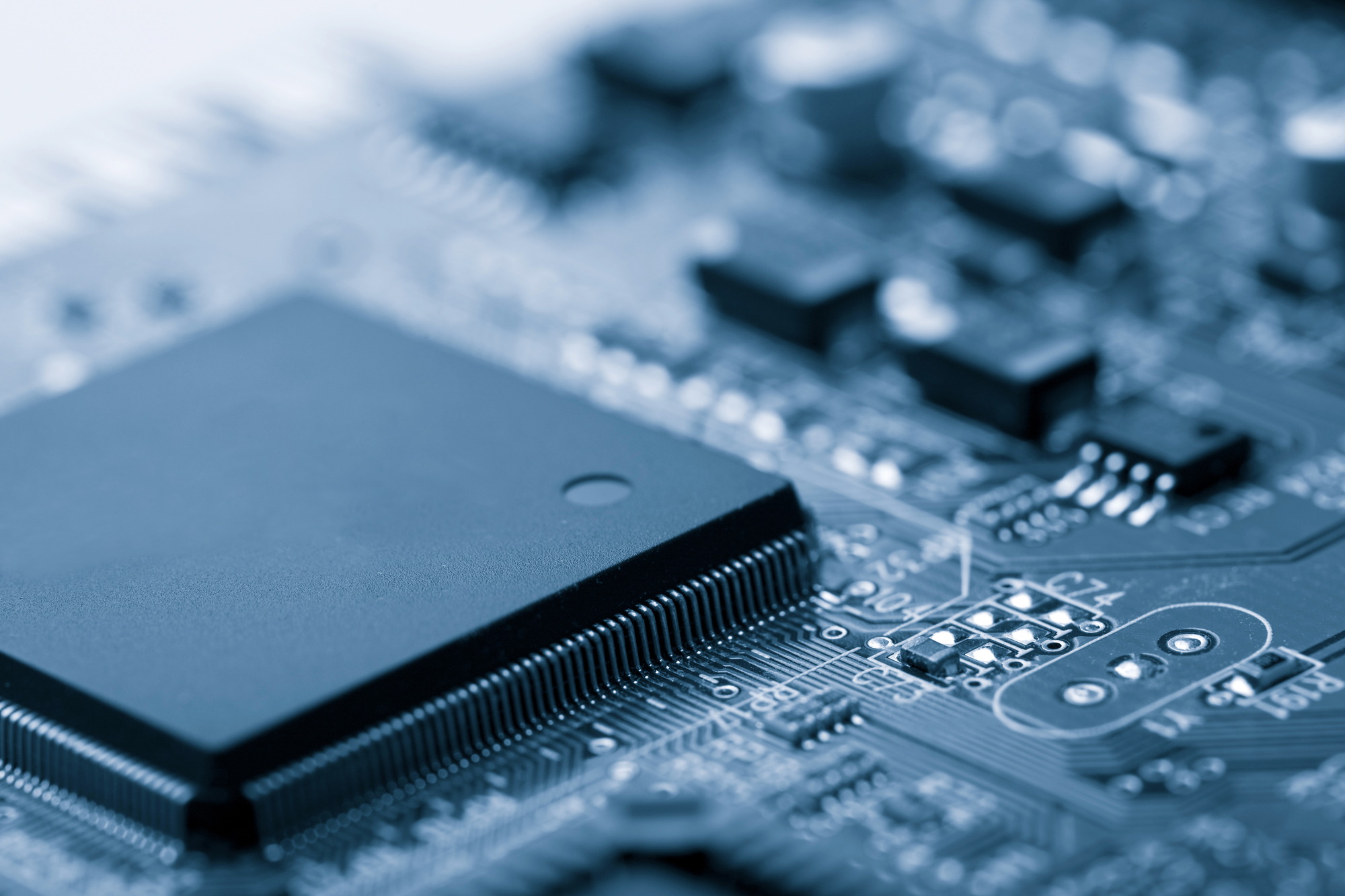

Wafer dicing machines are integral to the semiconductor industry, where they are used to precisely slice large semiconductor wafers into individual integrated circuits (ICs). These ICs are the building blocks for a vast range of electronic devices, such as smartphones, computers, tablets, and consumer electronics. The accuracy of wafer dicing ensures that each chip is properly separated with minimal stress, allowing for better performance and reliability. As the demand for smaller, more powerful, and energy-efficient devices grows, the need for high-precision wafer dicing becomes even more critical. These machines also play a key role in advanced semiconductor manufacturing processes like 5G technology, artificial intelligence (AI), and the Internet of Things (IoT), all of which require ultra-precise and high-yield production of microchips.

Semiconductor Industry

In the automotive industry, wafer dicing machines are essential for producing a variety of electronic components used in modern vehicles. These machines slice wafers into microchips that power essential automotive systems, such as sensors, microcontrollers, power management ICs, and advanced driver assistance systems (ADAS). The increasing trend towards electric vehicles (EVs), autonomous driving, and connected cars has made wafer dicing technology even more critical. As the automotive industry continues to evolve towards more sophisticated technologies, wafer dicing machines enable manufacturers to meet the stringent requirements of automotive standards, ensuring high reliability, safety, and longevity of critical components.

FAQ

A wafer dicing machine is used to slice semiconductor wafers into individual chips or die. These chips are then used in various electronic devices like smartphones, computers, and automotive components.

Get Touch With Us

CONTACT INFO

+86-635-8208968

info@rayfinetech.com

No. 7, Lijing Road, Pukou District, Nanjing, Jiangsu Province

English

English