Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

Are you looking for a welding technique that combines speed, precision, and minimal distortion?Laser welding is revolutionizing industries like aerospace, automotive, and electronics. This process uses a focused laser beam to join materials with exceptional accuracy.

In this article, we will explore how laser welding works, its advantages, and its impact on various industries. You will learn about its precision, efficiency, and the benefits that make it the preferred choice for high-quality welds.

Laser welding uses a highly focused laser beam to melt and fuse materials. The beam’s concentrated energy enables precise control over the heat application, which is vital for creating clean, strong joints without affecting the surrounding material. This focused energy melts the material at the joint, allowing it to fuse together as it cools and solidifies. Laser welding is especially ideal for working with thin materials and delicate, sensitive components due to its fine precision and control.

The laser welding process begins with a laser source generating a concentrated beam of light. The beam is directed at the material, typically using advanced motion systems or robotic-controlled mechanisms. The energy emitted by the laser is absorbed by the material’s surface, causing it to heat up rapidly. This intense, rapid heating results in the formation of a small molten pool at the weld site. This molten pool then cools and solidifies in a matter of milliseconds, ensuring a robust and reliable weld with minimal heat distortion.The quick solidification of the material and the minimal heat exposure around the weld zone result in a cleaner, more reliable weld, reducing the chance of defects such as warping or thermal damage.

The energy in laser welding is derived from the laser beam itself. There are various types of lasers used for welding, each producing different wavelengths of light. The energy from the laser beam is concentrated into a small spot, which allows for the precise targeting of the workpiece. The efficiency of the process depends on how well the laser energy is absorbed by the material. Different materials absorb laser energy at varying rates, which can influence the depth and quality of the weld.

Heat conduction welding is a method where the heat from the laser beam is conducted into the material’s surface. The process results in a shallow, smooth weld, making it ideal for welding thin materials. In this process, the laser melts the surface of the material, but it does not vaporize it. Instead, it allows for a controlled cooling process, ensuring that the joint solidifies cleanly and efficiently.This type of welding is particularly suitable for applications where the appearance of the weld is critical, such as in electronics, automotive components, and other high-precision industries.

Keyhole welding, also referred to as deep penetration welding, is used for welding thicker materials. In this method, the laser beam melts and vaporizes the material, creating a small cavity (the "keyhole") in the joint. As the laser moves forward, the molten material fills the cavity, forming a deep, narrow weld that is strong and highly durable.Keyhole welding is especially useful for high-speed welding of thicker materials, as it allows for deep penetration while minimizing heat distortion. This is particularly beneficial when welding thick metals such as stainless steel, titanium, or aluminum.

Laser-hybrid welding combines the best of both laser welding and arc welding. It uses the high-precision laser beam in conjunction with an electric arc to create a deeper, stronger weld. Laser-hybrid welding provides greater penetration compared to laser welding alone, making it ideal for industries that require deeper welds, such as shipbuilding and large-scale pipe manufacturing.

Tip: Laser-hybrid welding can be a more cost-effective solution for projects requiring deep, high-quality welds in thicker materials, as it combines the strengths of both welding methods.

| Feature | Laser Welding | MIG Welding | TIG Welding |

|---|---|---|---|

| Heat Affected Zone | Small, minimal distortion | Large, causes more distortion | Moderate, more heat input |

| Precision | High | Moderate | High |

| Speed | Very Fast | Moderate | Slow |

| Material Versatility | High | Moderate | Low |

One of the most significant advantages of laser welding is its small heat-affected zone (HAZ). The HAZ refers to the area around the weld that is not melted but has undergone physical and chemical changes due to high heat exposure. Laser welding’s precision and speed minimize the amount of heat transferred to surrounding areas, reducing the size of the HAZ and limiting potential damage to the material.A smaller HAZ ensures that the material retains its original properties, such as strength, hardness, and durability, after the welding process. This is particularly important for materials that are sensitive to heat, such as high-strength alloys.

Laser welding offers exceptional precision, making it perfect for welding small, intricate components. The focused nature of the laser beam allows for highly accurate welds with minimal distortion. This precision is especially important in industries like electronics and medical device manufacturing, where even the slightest distortion can compromise the product’s functionality.The low thermal input associated with laser welding also reduces the likelihood of warping and bending, ensuring that parts maintain their intended shape and structural integrity.

Laser welding is known for its speed, enabling manufacturers to produce more parts in less time. The high power of modern laser systems allows for rapid welding, making it suitable for high-volume production lines. The ability to complete welds quickly without compromising quality is one of the key reasons laser welding is favored in industries with tight production schedules.The speed of laser welding significantly boosts productivity and helps manufacturers meet high-demand orders more efficiently.

Laser welding is incredibly versatile and can be used to weld a wide range of materials, including metals like aluminum, stainless steel, and titanium, as well as thermoplastics and composites. The process can also handle material combinations that are traditionally difficult to weld, such as copper to aluminum joints.

Tip: For materials that are prone to cracking, such as high-carbon steels, special precautions are required to avoid issues during the welding process.

There are several types of lasers used in laser welding, each suited for different applications. The most common types include:

CO2 Lasers: These are versatile, high-powered lasers often used for welding thick metals.

Solid-State Lasers: Known for their high beam quality, these lasers are commonly used for precision welding in various industries.

Fiber Lasers: Offering high efficiency, fiber lasers are ideal for high-speed welding of thin materials.

| Laser Type | Power Characteristics | Efficiency | Common Applications |

|---|---|---|---|

| CO2 Lasers | High power, continuous or pulsed | Moderate | Thick metal welding, cutting |

| Solid-State Lasers | High beam quality, precision | High | Precision welding, thin materials |

| Fiber Lasers | Very high efficiency, high-speed | Very High | High-speed welding of thin materials, automotive parts |

Choosing the right laser depends on factors such as the material being welded, the thickness of the material, and the specific needs of the application.

Laser welding is often automated using robotic systems, which enhance both precision and efficiency. Automated systems can operate continuously, increasing production rates and reducing the risk of human error. These systems are especially beneficial in high-volume industries like automotive manufacturing, where consistency and speed are critical.

While the initial investment in laser welding equipment can be high, the long-term operational costs are typically lower than traditional welding methods. Laser welding systems require minimal maintenance and have a long lifespan, resulting in significant savings over time. Additionally, the reduced need for consumables such as filler materials helps lower ongoing operational costs.

In aerospace manufacturing, laser welding is used to produce strong, lightweight parts that meet the industry’s rigorous standards. The precision and speed of laser welding make it ideal for joining thin metals, such as aluminum, which are commonly used in aircraft components. Laser welding’s ability to produce high-strength joints without adding weight is crucial in this sector.

Laser welding is increasingly being adopted in automotive manufacturing for both lightweight and high-strength components. The ability to quickly and accurately weld thin materials helps reduce vehicle weight, improving fuel efficiency and performance. The speed and precision of laser welding also contribute to faster production times, making it ideal for high-demand automotive production lines.

Laser welding plays a critical role in the electronics industry, particularly in the assembly of small components such as battery tabs, circuit boards, and microelectronics. Its precision ensures that delicate components are welded without causing damage or distortion. In the battery industry, laser welding is used to make reliable, high-strength joints in lithium-ion batteries, ensuring safety and performance.

Laser welding technology continues to evolve, with innovations focused on improving efficiency, reducing costs, and expanding the range of materials that can be welded. Advances in fiber laser technology, for example, are making the process faster and more precise. New welding techniques, such as laser-hybrid welding, offer deeper and stronger welds, enabling laser welding to meet even more demanding applications.

Laser welding is considered an environmentally friendly process, as it reduces energy consumption compared to traditional welding methods. The precise application of heat minimizes material waste, and the ability to use energy-efficient lasers further enhances its sustainability. As industries continue to seek more sustainable manufacturing methods, laser welding’s energy efficiency will become even more valuable.

Laser welding provides many advantages over traditional methods, such as high precision, minimal heat distortion, and versatility with various materials. It is particularly valuable in industries like aerospace, automotive, and electronics. As technology progresses, laser welding is expected to play an increasingly vital role in manufacturing.

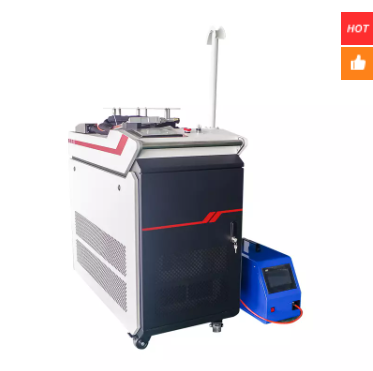

At Liaocheng Ray Fine Technology Co., Ltd., we offer high-quality laser welding products designed to enhance efficiency and accuracy in production processes. Our products provide lasting value with superior performance and reliability.

A: Laser welding is a precision technique that uses a focused laser beam to melt and fuse materials together.

A: Laser welding offers high precision, minimal heat distortion, and fast processing speeds, making it ideal for delicate components.

A: While initial costs are high, laser welding reduces long-term operational costs by eliminating filler materials and minimizing maintenance.

A: Laser welding works on metals like aluminum, titanium, and other materials like thermoplastics and composites.