Views: 0 Author: Site Editor Publish Time: 2025-09-24 Origin: Site

Lasers are transforming industries, from medical surgeries to manufacturing. These powerful tools are now essential in many applications, thanks to their precision and efficiency.

In this article, we will explore the five main types of lasers, focusing on their unique features, applications, and benefits. By understanding these laser types, you'll gain insight into choosing the right one for various needs.

Gas lasers use gases such as carbon dioxide (CO2), helium-neon (HeNe), and argon (Ar) as the gain medium. In these lasers, an electrical current passes through the gas, exciting the atoms or molecules to a higher energy state. As the atoms return to their lower energy state, they release energy in the form of photons, producing a laser beam. The specific gas used determines the wavelength and properties of the laser light.

Gas lasers have a wide variety of industrial, medical, and scientific applications.

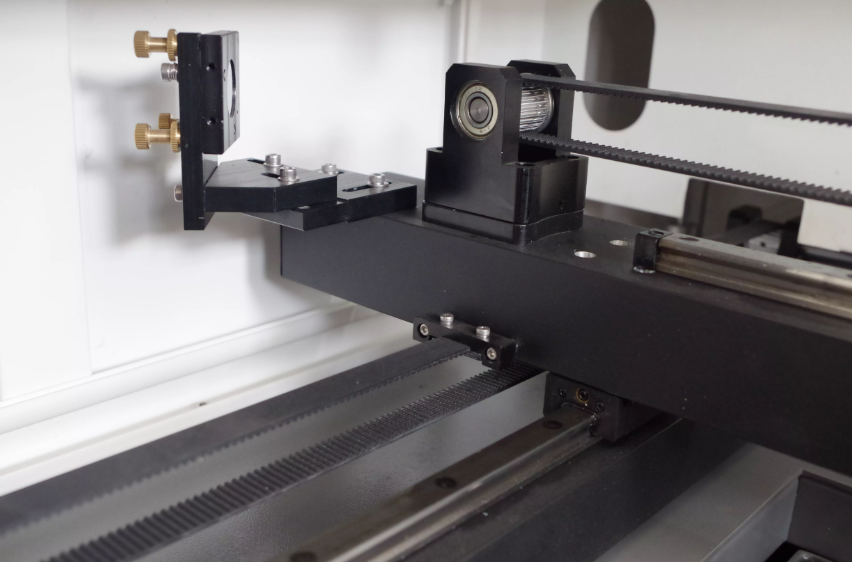

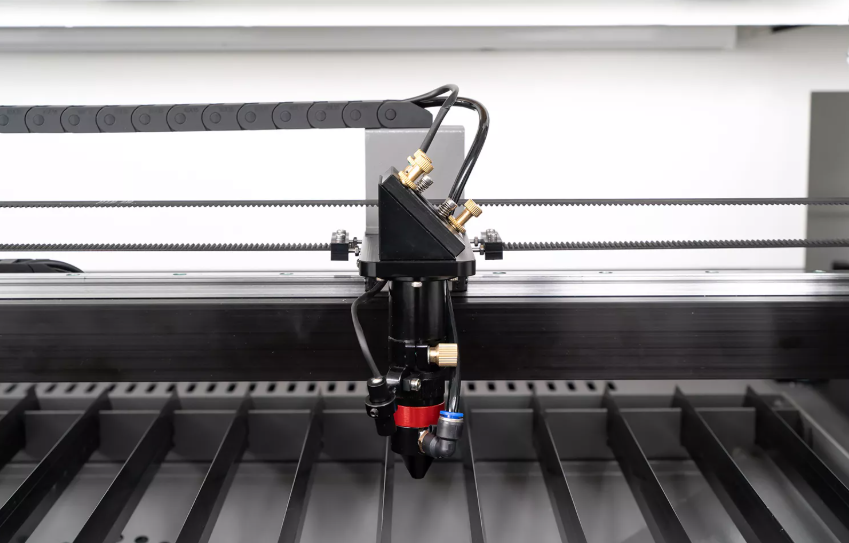

Industrial uses: CO2 lasers are particularly known for their high power and versatility. They are used for material processing tasks such as cutting, welding, engraving, and marking on materials like metal, plastic, and ceramics. These lasers offer high energy and precision, which makes them indispensable in modern manufacturing.

Medical uses: Gas lasers, especially HeNe lasers, are commonly used in eye surgeries, including treatments for retinal conditions and cataract removal. In addition to eye surgeries, they are also utilized in diagnostic equipment for various medical conditions.

Gas lasers, particularly CO2 lasers, are highly efficient and capable of delivering powerful laser beams. They are well-suited for industrial tasks requiring high energy output and precision. They are also known for their long beam coherence, making them effective for applications such as holography and spectroscopy.

Solid-state lasers use a solid gain medium, typically a crystal or glass that has been doped with rare-earth elements like neodymium (Nd), erbium (Er), and ytterbium (Yb). These materials absorb light from an external source, such as a flash lamp, and re-emit the absorbed energy as a laser beam. The use of solid materials makes these lasers more compact and efficient compared to gas lasers.

Nd:YAG laser: One of the most common and versatile solid-state lasers. The Nd:YAG laser is used in both industrial and medical applications due to its efficiency and high power output. It is commonly used in material processing tasks like laser cutting and welding, as well as in medical procedures such as laser surgeries and dental applications.

Ruby laser: The ruby laser is the first solid-state laser ever created, using a synthetic ruby crystal as its gain medium. While its use is now limited to a few niche applications, it holds historical significance and is still used in some laser light show applications.

Applications: Solid-state lasers are widely used in material processing, where precision and high power are required. They are commonly used for laser engraving, marking, and cutting in industries such as automotive and electronics. Additionally, they play a significant role in medical procedures like kidney stone removal and skin resurfacing.

Benefits: Solid-state lasers are highly efficient and provide a good balance between power, precision, and cost. They are also more compact and durable than gas lasers, making them suitable for a wider range of applications. Their high efficiency means they are commonly used in high-power tasks, where maintaining a steady beam is essential.

Fiber lasers are a type of solid-state laser that uses an optical fiber as the gain medium. The fiber is typically doped with rare-earth elements such as ytterbium or erbium. The use of optical fiber offers several advantages, including better beam quality, smaller size, and the ability to maintain a consistent laser output over time.

Fiber lasers are known for their exceptional energy efficiency and high beam quality. The fiber design allows for better heat dissipation, which prevents overheating and ensures consistent performance. This makes fiber lasers more compact, with lower operating costs and minimal maintenance compared to traditional gas or solid-state lasers.

Material processing: Fiber lasers are widely used in the manufacturing industry for tasks such as laser cutting, engraving, and welding. Their small size and precision make them perfect for high-precision applications that require fine detail and accuracy.

Medical applications: Fiber lasers are increasingly being used in medical treatments, particularly for minimally invasive procedures, such as laser surgeries and dental treatments. Their precision allows for delicate surgeries with minimal damage to surrounding tissue.

Emerging technologies: Fiber lasers are being explored for use in directed energy weapons and advanced technologies in fields such as telecommunications and remote sensing.

Liquid lasers, also known as dye lasers, use an organic dye dissolved in a liquid solvent as the gain medium. The dye is capable of being tuned to different wavelengths, making dye lasers highly versatile. By adjusting the dye, the laser can produce light in a wide range of wavelengths, allowing for more specialized applications.

Laser spectroscopy: Liquid lasers are used in research fields that require precise wavelength control, such as in spectroscopy, where they help analyze the composition of materials and substances.

Medical treatments: Dye lasers are used in a variety of medical treatments, including birthmark removal and the treatment of certain skin conditions. Their tunability makes them ideal for targeting specific wavelengths needed for particular treatments.

Isotope separation: Dye lasers are used in isotope separation for nuclear research, where precise wavelength tuning is required to interact with specific isotopes.

The primary advantage of dye lasers is their tunable wavelength capability. This allows for a wider range of applications compared to other laser types, making them ideal for research and specialized medical treatments.

Semiconductor lasers, also known as laser diodes, use semiconductor materials like gallium arsenide (GaAs) as the gain medium. When current passes through the material, it triggers the emission of photons, producing a laser beam. These lasers are compact, cost-effective, and widely used in everyday technology.

Barcode scanners: Semiconductor lasers are essential in barcode scanners, which are used in retail and logistics.

Laser pointers: These lasers are commonly used in educational and business presentations, making them a ubiquitous tool in classrooms and meetings.

Telecommunications: Laser diodes are used in optical fiber communication systems, enabling high-speed data transmission over long distances.

emiconductor lasers are compact, efficient, and inexpensive. Their small size makes them perfect for use in consumer electronics and portable devices, such as barcode scanners, laser pointers, and optical drives. This miniaturization allows for easy integration into a wide variety of products, enabling compact designs without compromising on performance.

| Laser Type | Gain Medium | Efficiency | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Gas Lasers | CO2, HeNe, Argon | Moderate | Cutting, welding, medical surgeries, holography | High power, long beam coherence | Large size, high maintenance |

| Solid-State Lasers | Crystals or glasses | High | Material processing, LIDAR, medical surgeries | High power, efficient, compact | Can be complex to cool, costly |

| Fiber Lasers | Optical fiber doped | Very high | High-precision cutting, medical, defense | Compact, energy-efficient, low maintenance | Lower peak power than solid-state |

| Liquid Lasers | Organic dye | Moderate | Spectroscopy, medical treatments | Tunable wavelength | Less common, complex to operate |

| Semiconductor Lasers | GaAs, InGaAs | Very high | Barcode scanners, telecom, consumer electronics | Small, cost-effective, reliable | Lower power output |

Each of the five types of lasers has its own set of strengths and weaknesses. Gas lasers, such as CO2 lasers, are known for their high power, while solid-state lasers offer versatility and high efficiency. Fiber lasers excel in compactness and precision, whereas liquid lasers are valued for their tunability. Semiconductor lasers are widely used in compact devices but typically offer lower power output.

When selecting a laser, it's essential to consider the specific requirements of the task at hand. For industrial and medical applications that require high power, solid-state or gas lasers may be ideal. For tasks requiring precision and compactness, fiber lasers are the preferred choice. For specialized applications like research and isotope separation, liquid lasers offer the best solution.

Lasers are essential in various modern technologies, from industrial applications to medical treatments. Understanding the five main types—gas, solid-state, fiber, liquid, and semiconductor—helps in choosing the right laser for specific needs. As technology advances, lasers will play an increasingly important role in diverse fields.

For high-quality laser solutions,Liaocheng Ray Fine Technology Co., Ltd. offers advanced products designed to provide value through precision and efficiency, serving industries worldwide.

A: The five main types of lasers are gas, solid-state, fiber, liquid, and semiconductor lasers, each with unique applications.

A: Fiber lasers use optical fibers for high efficiency and precise beam quality, ideal for material processing.

A: Gas lasers provide high power and are commonly used for cutting, welding, and medical treatments.

A: Semiconductor lasers are used in electronics like barcode scanners and optical communication due to their compact size.