| Availability: | |

|---|---|

| Quantity: | |

RF-1390 RF-1310 RF-6090

RAY FINE

845611

ccd camera Desktop co2 laser engraver cutter machines wood cuts laser cut machine 100w 130w 150w 200w 960 1390 1610 engraving

CO2 laser cutter with CCD camera integrates a vision system (CCD = Charge-Coupled Device) into a CO₂ laser cutting platform. The CCD camera captures high-resolution images of workpieces, enabling automatic detection of material edges, pre-printed patterns, or registration marks. This allows the machine to dynamically adjust cutting paths without manual alignment.

Woven/Embroidered Labels: Automated contour cutting of woven labels and embroidered patches with ±0.1mm accuracy, compensating for fabric deformation

Garment Components: Cutting multi-layer fabrics (e.g., leather, synthetic textiles) for shoes, bags, and clothing with sealed edges

Roll Material Processing: Continuous cutting of printed textile rolls with automatic registration mark detection

Acrylic/Plastic Signage: Precision cutting of acrylic letters, logos, and braille signs using vision-based alignment to avoid manual positioning812.

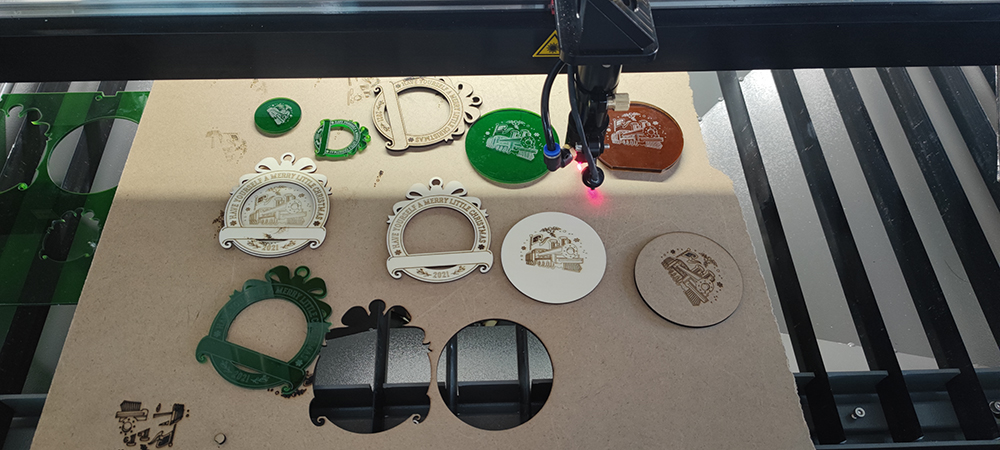

Display Components: Creating intricate backlit panels and decorative elements from wood or composite materials

Leather Goods: Custom-cutting wallets, belts, and accessories without mechanical contact, preserving material integrity

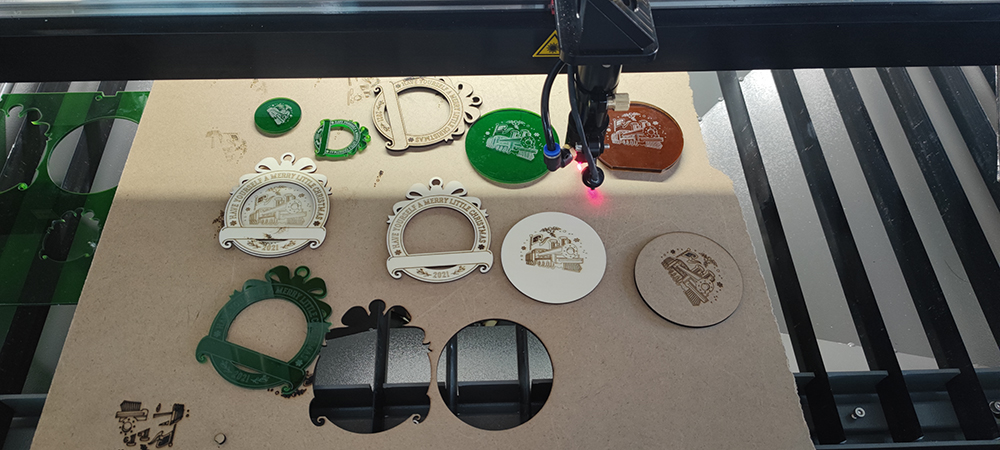

Wooden Models/Toys: Producing architectural models, puzzles, and art pieces from plywood or MDF with complex geometries

Luxury Packaging: Cutting dielines for custom boxes and structural prototypes with zero setup time

Sample Development: Rapid iteration of textile or paper packaging designs for small-batch production

STEAM Projects: Enabling students to cut educational models (e.g., topographic maps, mechanical parts) from wood/acrylic

Artistic Creations: Facilitating DIY jewelry, home decor, and personalized gifts using vision-assisted alignment

Technical parameter

| Model | YJ-CO2-1390 | |||

| Focus lens | USA imported D20mm/FCL63.5mm | |||

| Power supply | AC220/110V±10% 50/60hz | |||

| Working area | 1300*900mm | |||

| Laser heads quantity | 1 | |||

| Laser power | 80-300W(optional) | |||

| Max moving speed | 500mm/s | |||

| Laser energy control | by LCD panel or software | |||

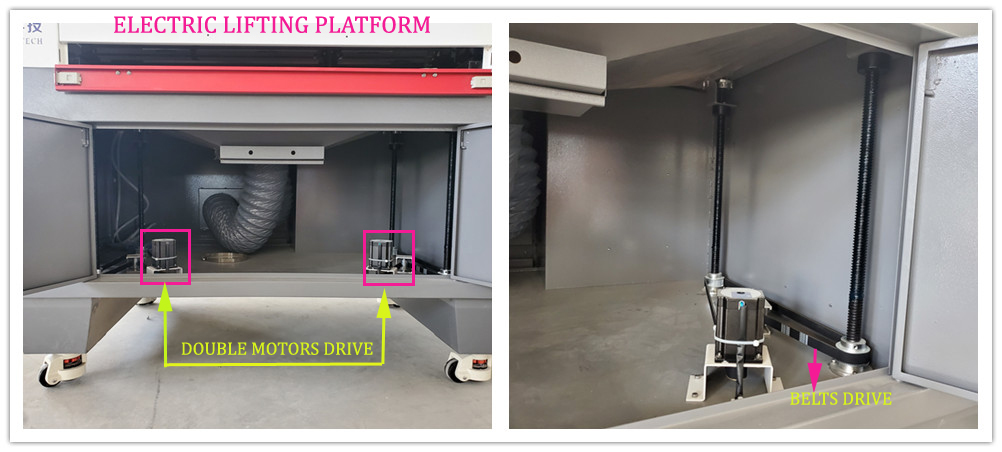

| Working table | Up&down Aluminum knife +Honeycomb table | |||

| Locating precision | <0.01mm | |||

| Min shaping character | letter 0.5mm, Chinese 0.5mm | |||

| Operating temperature | -5℃-35℃ | |||

| Resolution ratio | 4500dpi | |||

| Control program | RDWORKS | |||

| Data transfer interface | USB | |||

| System environment | Win7/8/10 | |||

| Cooling way | Chiller CW5200 with protection system | |||

| Graphic format supported | The file which CorelDraw, Photo shop, Auto-CAD can identify | |||

| Compatible software | CorelDraw, Auto-CAD etc. | |||

| Cutting thickness | 0-25 mm (depends on different materials) | |||

| Color separation | Separation of cutting up to 256 colors | |||

| Red dot pointer | yes | |||

| Open door safety | yes | |||

| Packing | Plywood | |||

| Net weight | 350kgs | |||

| gross weight | 450kgs | |||

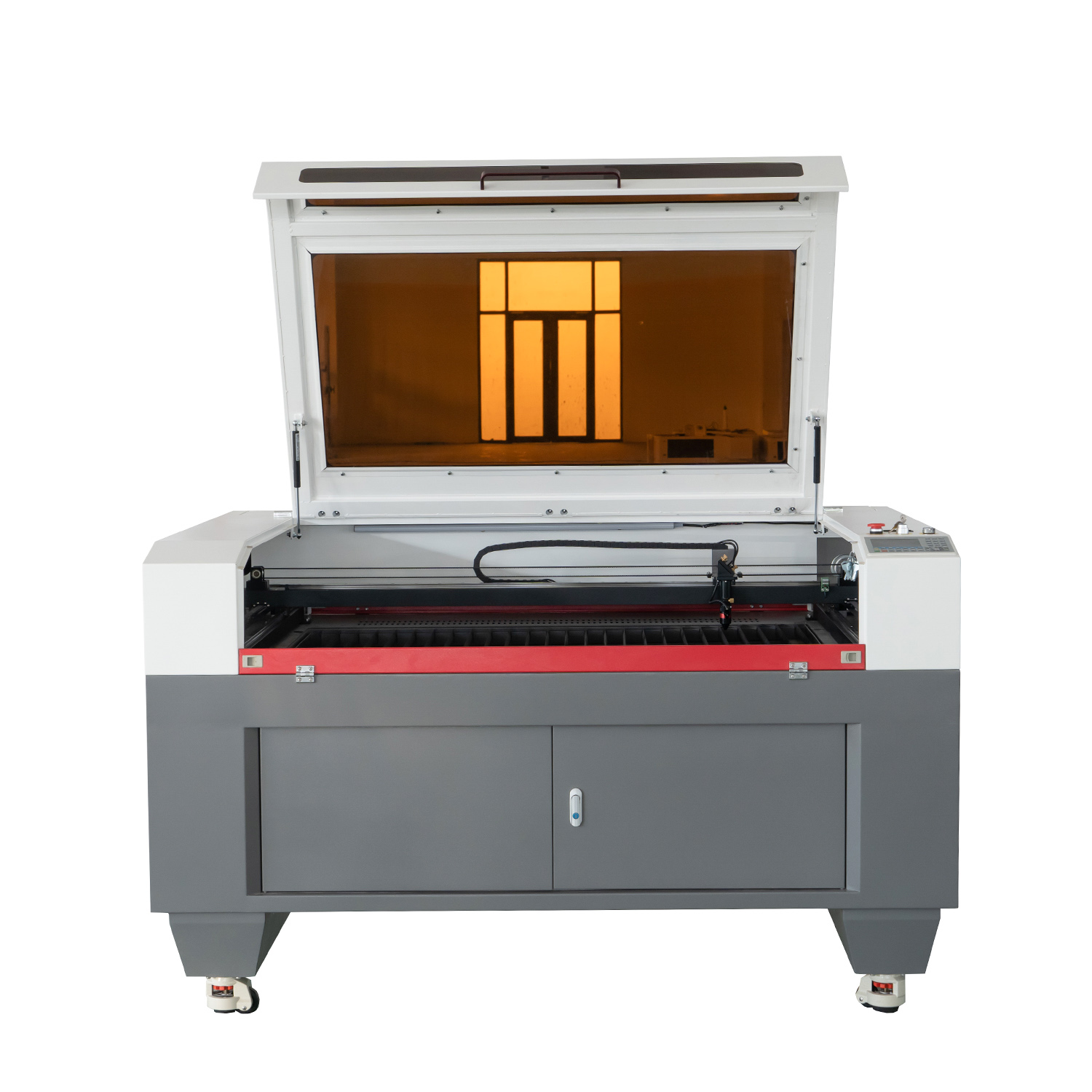

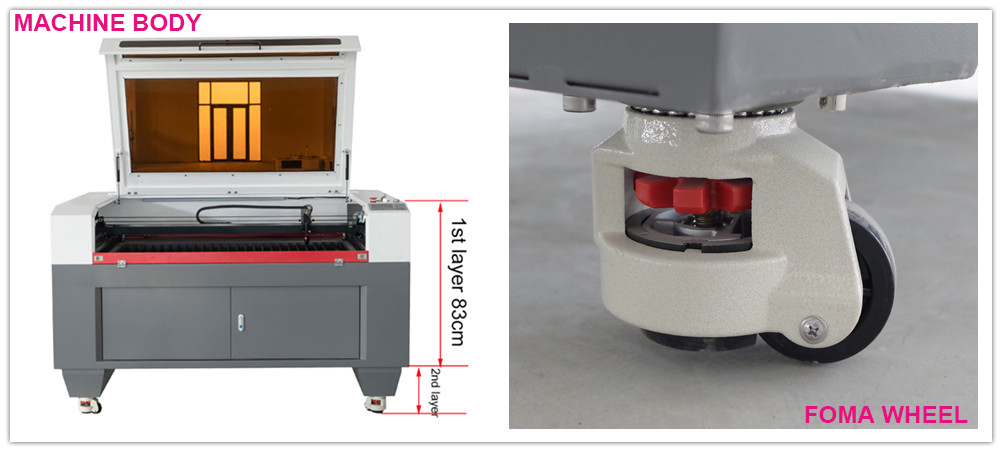

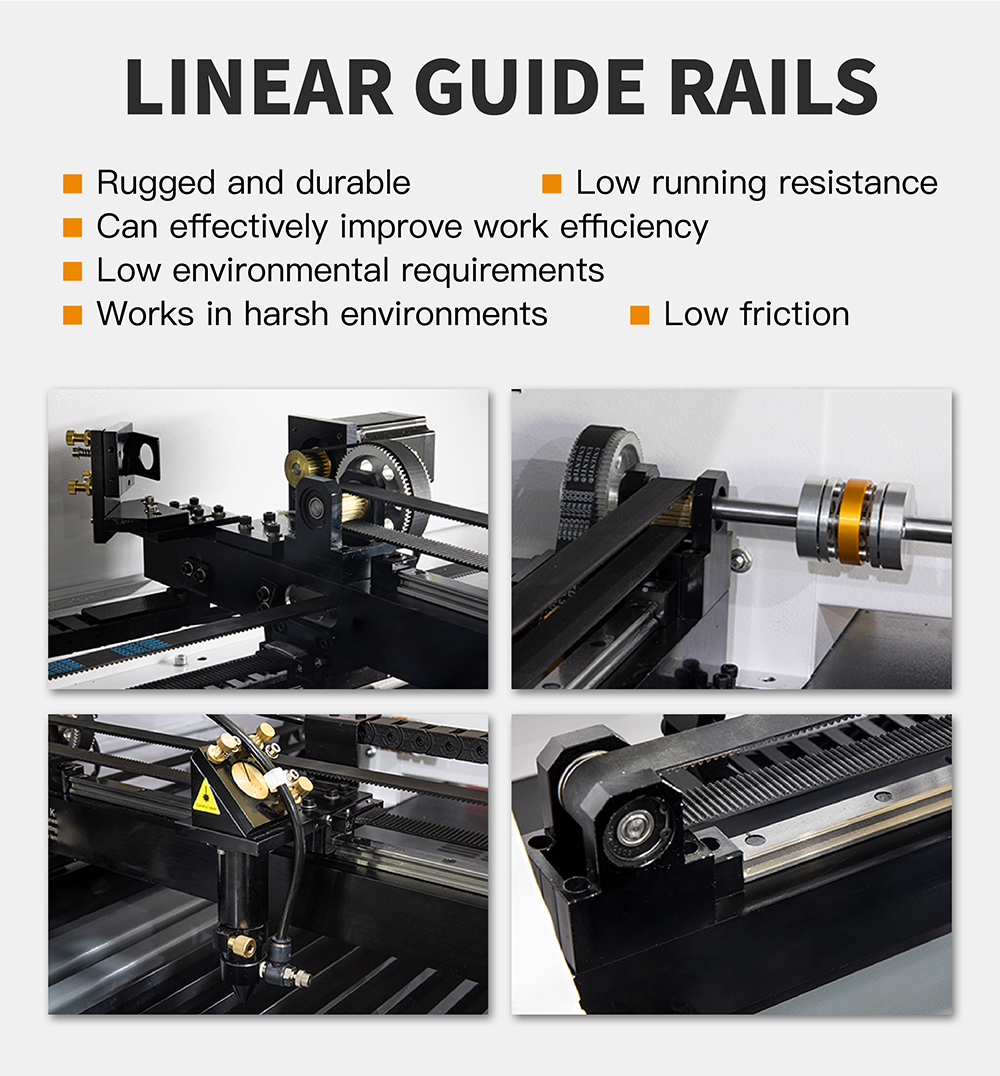

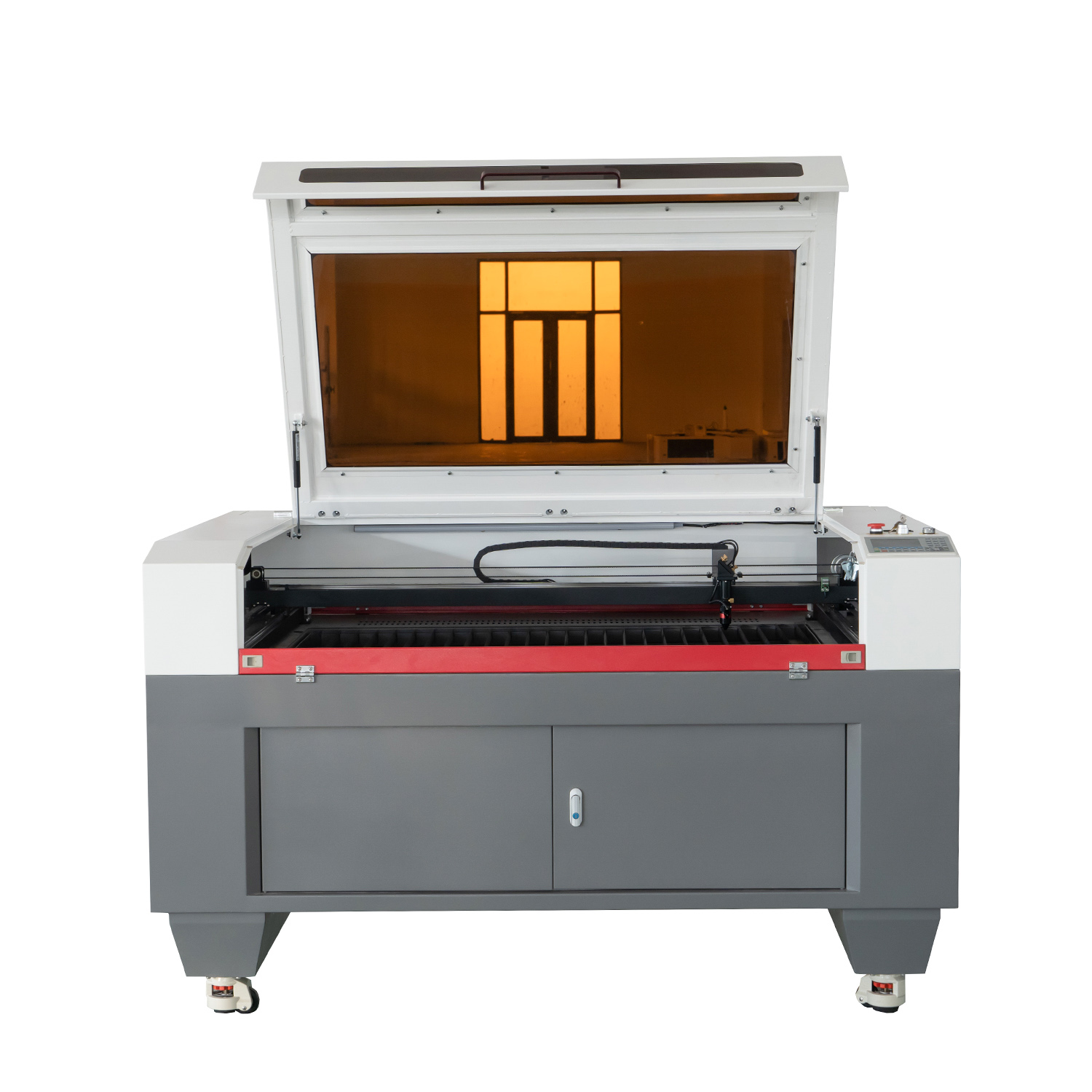

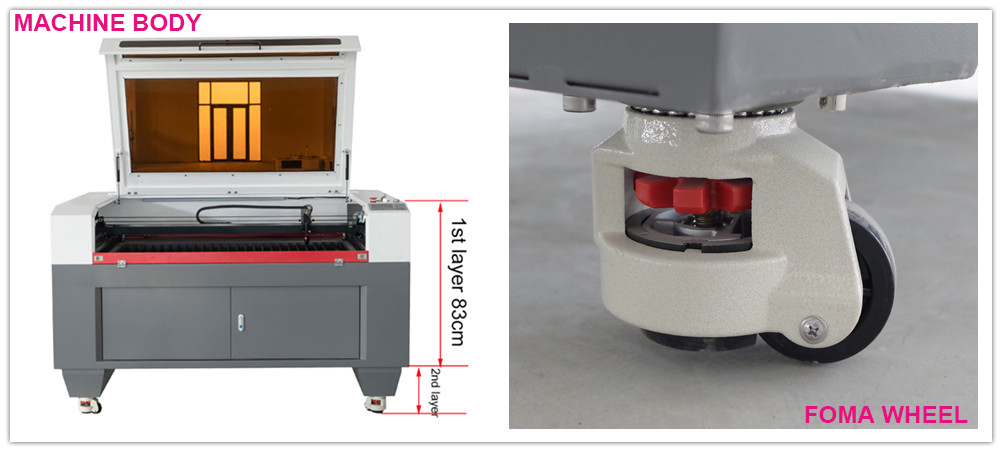

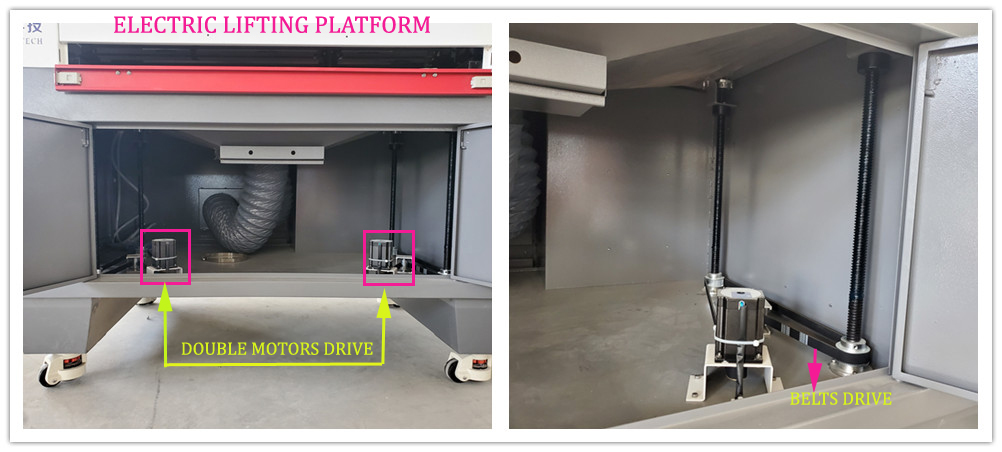

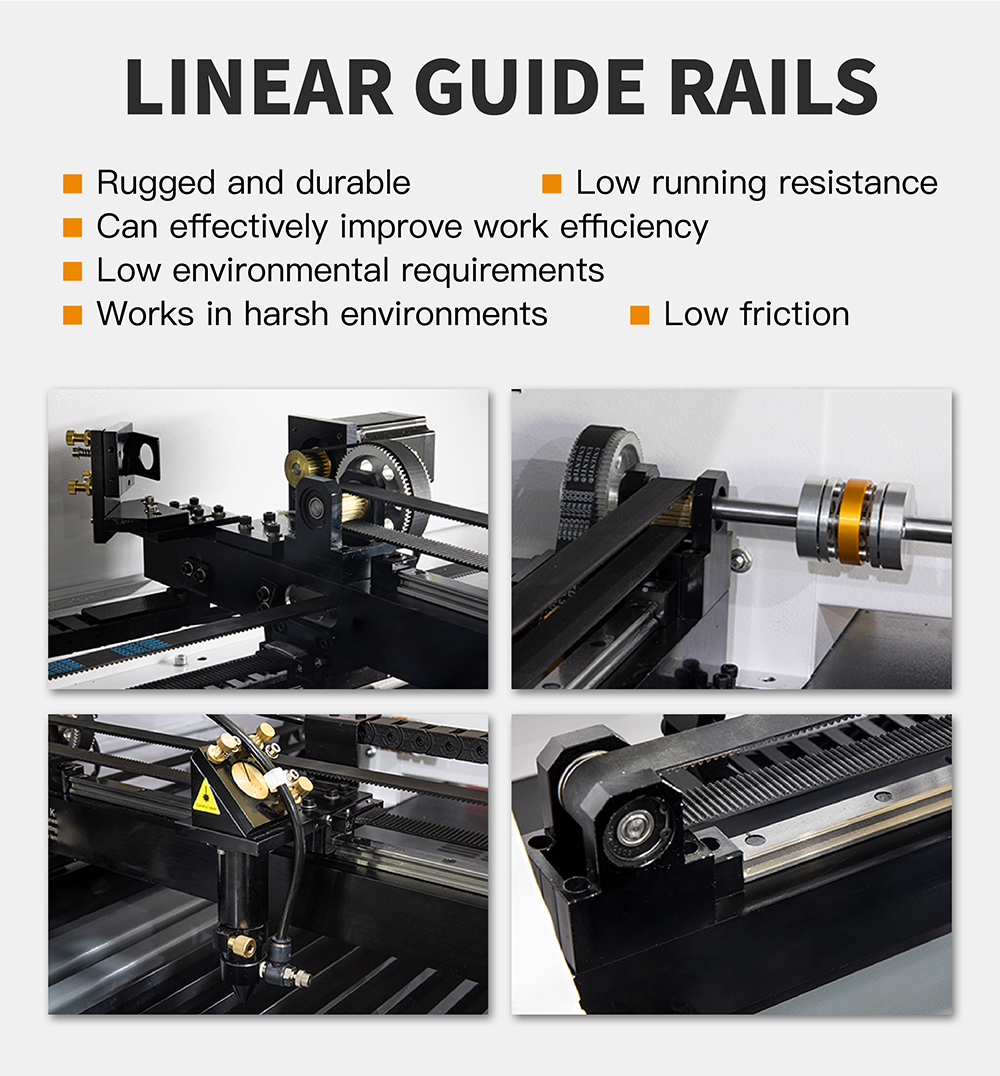

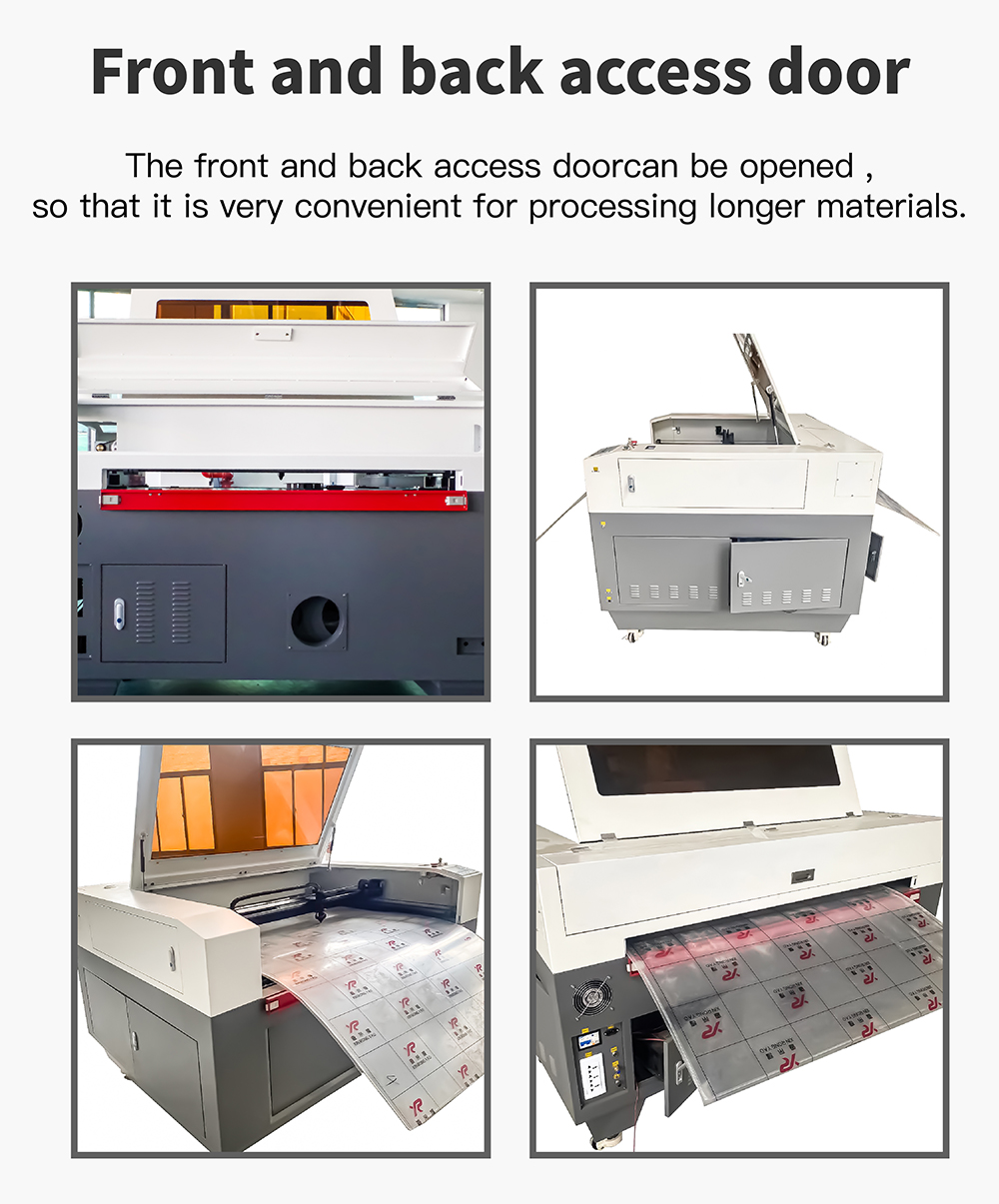

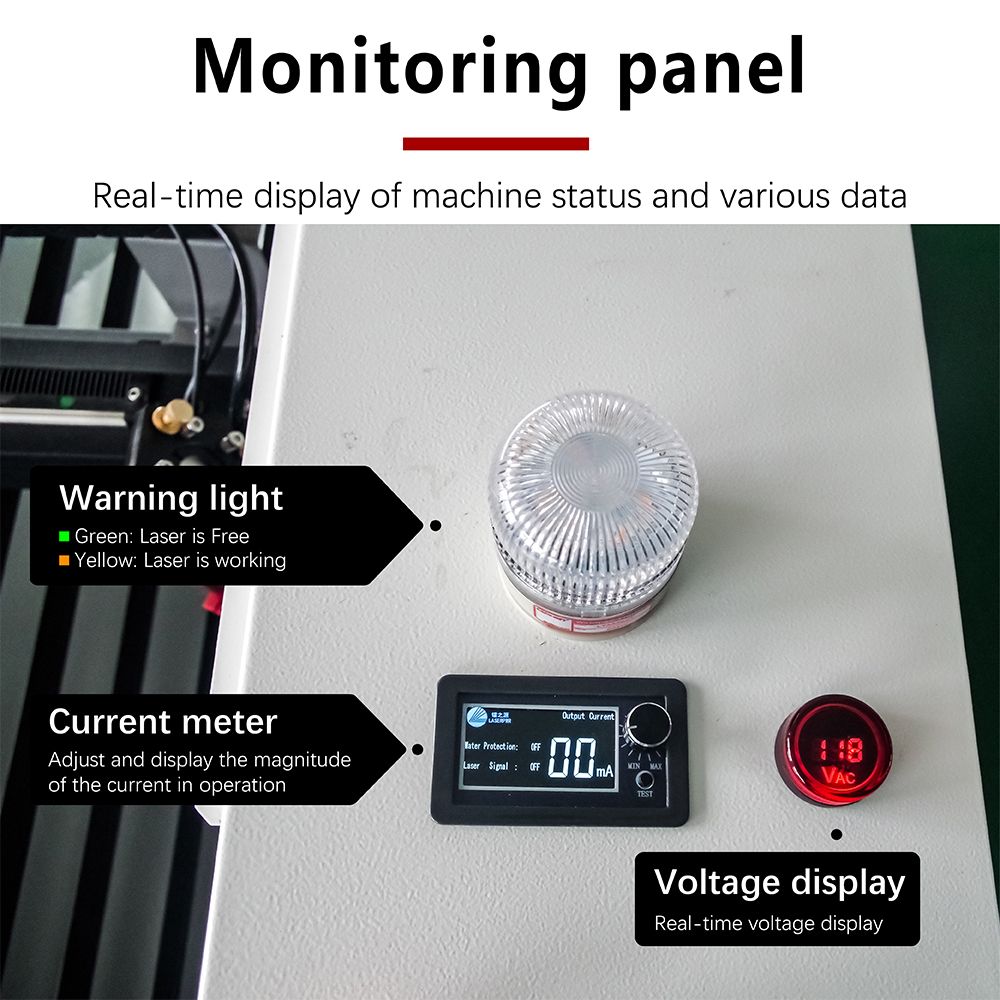

Machine details

Inquiry to sales05@rayfinetech.com, thank you :)

ccd camera Desktop co2 laser engraver cutter machines wood cuts laser cut machine 100w 130w 150w 200w 960 1390 1610 engraving

CO2 laser cutter with CCD camera integrates a vision system (CCD = Charge-Coupled Device) into a CO₂ laser cutting platform. The CCD camera captures high-resolution images of workpieces, enabling automatic detection of material edges, pre-printed patterns, or registration marks. This allows the machine to dynamically adjust cutting paths without manual alignment.

Woven/Embroidered Labels: Automated contour cutting of woven labels and embroidered patches with ±0.1mm accuracy, compensating for fabric deformation

Garment Components: Cutting multi-layer fabrics (e.g., leather, synthetic textiles) for shoes, bags, and clothing with sealed edges

Roll Material Processing: Continuous cutting of printed textile rolls with automatic registration mark detection

Acrylic/Plastic Signage: Precision cutting of acrylic letters, logos, and braille signs using vision-based alignment to avoid manual positioning812.

Display Components: Creating intricate backlit panels and decorative elements from wood or composite materials

Leather Goods: Custom-cutting wallets, belts, and accessories without mechanical contact, preserving material integrity

Wooden Models/Toys: Producing architectural models, puzzles, and art pieces from plywood or MDF with complex geometries

Luxury Packaging: Cutting dielines for custom boxes and structural prototypes with zero setup time

Sample Development: Rapid iteration of textile or paper packaging designs for small-batch production

STEAM Projects: Enabling students to cut educational models (e.g., topographic maps, mechanical parts) from wood/acrylic

Artistic Creations: Facilitating DIY jewelry, home decor, and personalized gifts using vision-assisted alignment

Technical parameter

| Model | YJ-CO2-1390 | |||

| Focus lens | USA imported D20mm/FCL63.5mm | |||

| Power supply | AC220/110V±10% 50/60hz | |||

| Working area | 1300*900mm | |||

| Laser heads quantity | 1 | |||

| Laser power | 80-300W(optional) | |||

| Max moving speed | 500mm/s | |||

| Laser energy control | by LCD panel or software | |||

| Working table | Up&down Aluminum knife +Honeycomb table | |||

| Locating precision | <0.01mm | |||

| Min shaping character | letter 0.5mm, Chinese 0.5mm | |||

| Operating temperature | -5℃-35℃ | |||

| Resolution ratio | 4500dpi | |||

| Control program | RDWORKS | |||

| Data transfer interface | USB | |||

| System environment | Win7/8/10 | |||

| Cooling way | Chiller CW5200 with protection system | |||

| Graphic format supported | The file which CorelDraw, Photo shop, Auto-CAD can identify | |||

| Compatible software | CorelDraw, Auto-CAD etc. | |||

| Cutting thickness | 0-25 mm (depends on different materials) | |||

| Color separation | Separation of cutting up to 256 colors | |||

| Red dot pointer | yes | |||

| Open door safety | yes | |||

| Packing | Plywood | |||

| Net weight | 350kgs | |||

| gross weight | 450kgs | |||

Machine details

Inquiry to sales05@rayfinetech.com, thank you :)